KM3NeT: designing an underwater neutrino detector is also a mechanical engineering challenge

Alin Ilioni is a research engineer in the mechanical department of the AstroParticule & Cosmology laboratory (APC, Université de Paris / CNRS / CEA) since 2018. With other fellow engineers and physicists of the European project KM3NeT, he is in charge of developing the Calibration Base of the KM3NeT/ORCA detector, within the framework of the ARGOS Interface project, which receives funding from LabEx UnivEarthS.

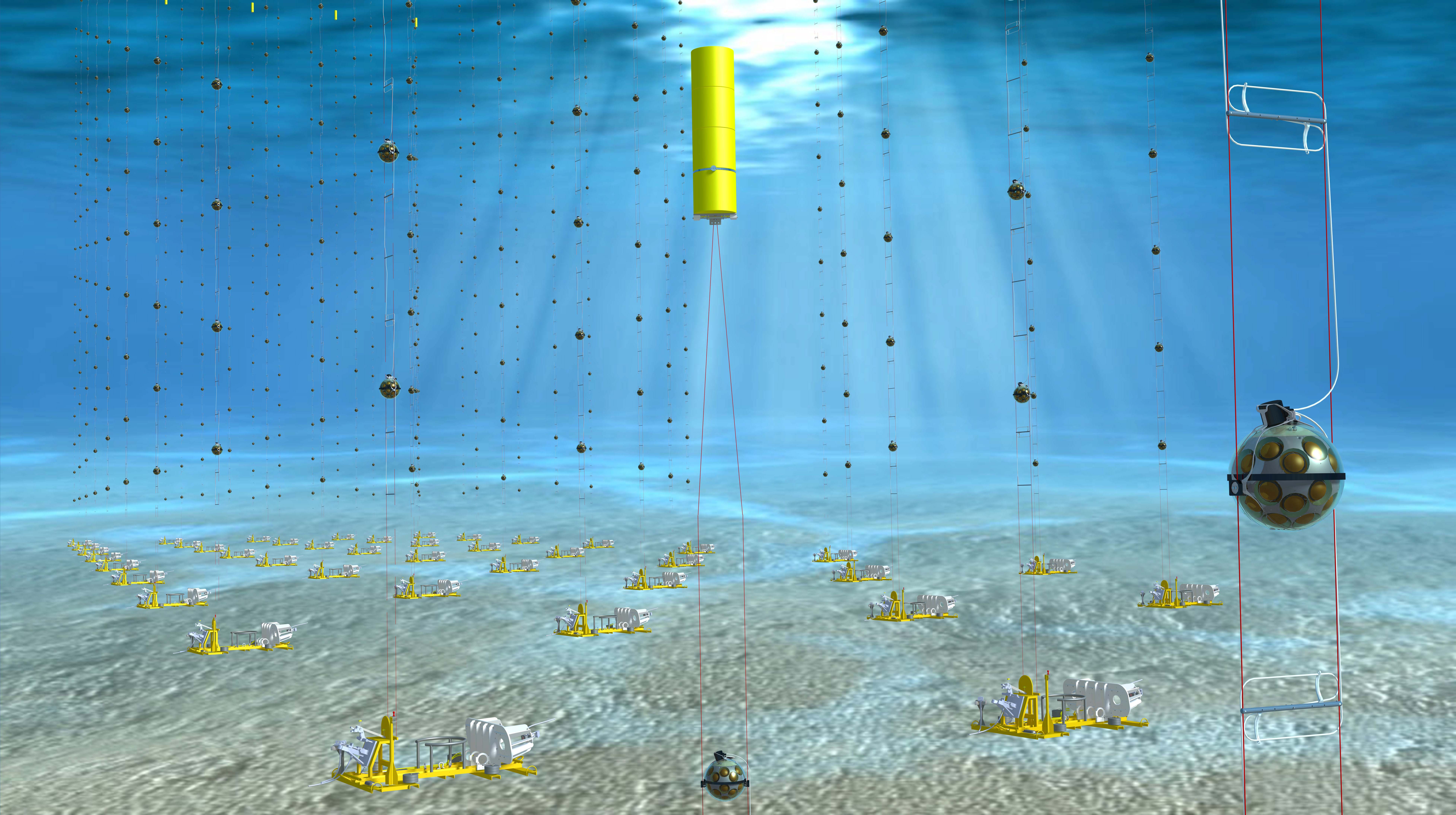

KM3NeT is a new generation neutrino telescope currently being deployed in the Mediterranean Sea. The objective of this telescope is to discover the sources of high-energy neutrinos in the Universe, as well as to determine the mass hierarchy of neutrinos, major questions that still question researchers in the fields of astrophysics and particle physics.

For this purpose, detectors are currently under construction at two sites: ORCA off Toulon in France, and ARCA off Capo Passero in Sicily. Eventually, several hundred lines of flexible detectors, ranging in height from 200m (ORCA) to 700m (ARCA) will be deployed on the seabed. Each of these lines supports 18 optical modules, allowing the detection of the very weak light generated by neutrinos when they interact with the material surrounding the detector after they have crossed the Earth, and thus to trace their path.

Neutrinos are electrically neutral particles with very small masses that interact very little with matter and can be emitted by violent astrophysical phenomena located far beyond the solar system, in our Galaxy or beyond. The detection of astrophysical neutrinos represents a real scientific and technical challenge because it requires the instrumentation of gigantic detection volumes (the final volume of KM3NeT will be of the order of 5km3) in a medium (here the abyss of the Mediterranean Sea) far from ideal for the proper functioning of electronic and optical measurement instruments. It is up to mechanical engineers like Alin Ilioni, among others, to take up this challenge.

Alin arrived in France ten years ago, as part of an academic exchange program between the Polytechnic University of Timisoara in Romania, where he is originally from, and l’école des Arts et Métiers in Cluny. Alin then joined a master’s program at l’ENSTA Bretagne in Brest, where he undertook a thesis in partnership with IFREMER (French Research Institute for Exploitation of the Sea). “My thesis subject consisted in studying the influence of water on the mechanical properties of adhesives used in underwater mechanical assemblies such as tidal turbine blades. For this, I used finite element models to simulate the diffusion of water in the system in order to predict its mechanical behavior and to follow its evolution over time.“

This expertise in submerged mechanical systems and an already existing appetite for the field of astrophysics led Alin to join the Astroparticle and Cosmology Laboratory (APC) in 2018 to contribute to the KM3NeT experiment. Her work and that of her team consists, among other things, in designing and integrating the calibration base of the ORCA detector and some of its instruments. An essential mission, for which Alin is the technical project leader of the subsystem within the KM3NeT collaboration. This base is indeed one of the main elements of the KM3NeT optical module time and position calibration system, which is crucial to achieve the detector performance objectives.

In addition to a cylinder containing the electronic control system, the steel structure, which will rest at a depth of 2,500 meters, houses three instruments to contribute to the calibration of the detector. Among the instruments are a laser to calibrate the optical modules with nanosecond precision, as well as a hydrophone and an acoustic transmitter, contributing to the ORCA detector’s line triangulation positioning system.

This structure will also serve as a connection point for another instrumented line carrying sensors that will allow monitoring the environmental conditions at the detector site: temperature, pressure, salinity, current velocity… parameters that may also be of interest to oceanographers, particularly those from the Institut de Physique du Globe de Paris, an APC partner in the ARGOS project.

In order to protect these electronic instruments from water and the overwhelming underwater pressure, they are integrated in hermetic cylindrical titanium containers. As these instruments must remain functional throughout the 20 years of experience, it is essential to ensure that these containers can properly protect the instruments from the underwater environment.

This is where Alin’s expertise comes into play: using models and simulations, he studies the mechanical properties of these containers, which are subject to the expected environmental constraints. This task proved particularly difficult in the case of the cylinder housing the laser, which includes a transparent – and therefore fragile – part that allows the light emitted to reach the detector’s various optical modules. A real challenge.

Indeed, it is no longer one but two materials that must be interfaced: the titanium cylinder, similar to the containers used for the various marine applications, and the quartz glass, located on one of the faces of the cylinder and which constitutes the transparent part necessary for the laser emission. Two materials that react differently to the influence of water, immense pressures or temperatures, and that must be made to coexist without the water inviting itself into the equation… “It’s very delicate, especially at the interface between these two materials,” explains Alin Ilioni. “There are a lot of mechanical constraints to take into account, much more than if we had a simple titanium cylinder. There’s no room for error.”

It took Alin and his colleagues many months of modeling, calculations and simulations before they were able to design a laser container with the optimal dimensions and mechanical properties. The container is now built and being tested. If the results are conclusive, it will be deployed, along with the rest of the calibration base, early next year in the dark abyss of the Mediterranean Sea…